Hi, I'm Ava Rizzico

Mechanical Engineering and Design major at Northeastern University

Red Vest at FYELIC, Northeastern University College of Engineering

Hi, I'm Ava Rizzico

Mechanical Engineering and Design major at Northeastern University

Red Vest at FYELIC, Northeastern University College of Engineering

Shrammer

An accessible alternative to the traditional hammer: this mantis shrimp inspired device is powered by a simple ratchet and spring, and can easily punch a nail into the wall in a single shot.

Crabs in a Bucket

Etiam tristique libero eu nibh porttitor amet fermentum. Nullam venenatis erat id vehicula ultrices sed ultricies condimentum.

Hanging Planters

Hanging planters are a great way to save space in a small apartment, but how can you grow plants such as herbs or flowers that require water drainage in a hanging pot?

Video Game Curriculum

For my senior high school project, I wrote a curriculum which teaches students how to create video games in the Unity game engine, which is currently being used at Manchester Essex Regional High School.

Interested in working with me?

I am currently searching for my Fall 2026 Co-Op.

Feel free to contact me below.

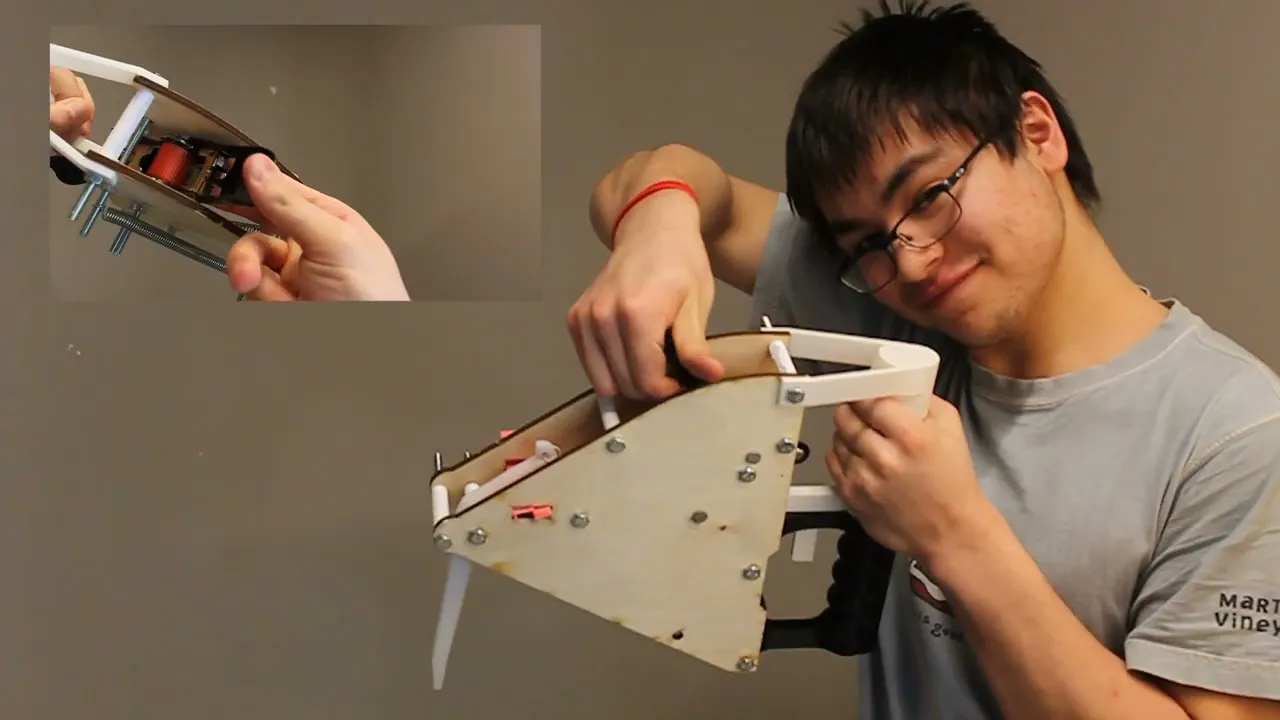

Shrammer

Sparked by a class assignment, the Shrammer is a spring-loaded hammer, inspired by the Mantis Shrimp, and built to aid elderly and disabled autonomy. Costing no more than $53 to manufacture, this incredibly affordable alternative to the traditional hammer could easily bring independence back into the lives of many.

Inspired by the punch of a mantis shrimp, while the Shrammer takes a few seconds to properly load by cranking the ratchet, the swing of the arm can easily punch a nail into a wall. This allows for a single strike to be able to do any job that a traditional hammer would take a few strikes to achieve.

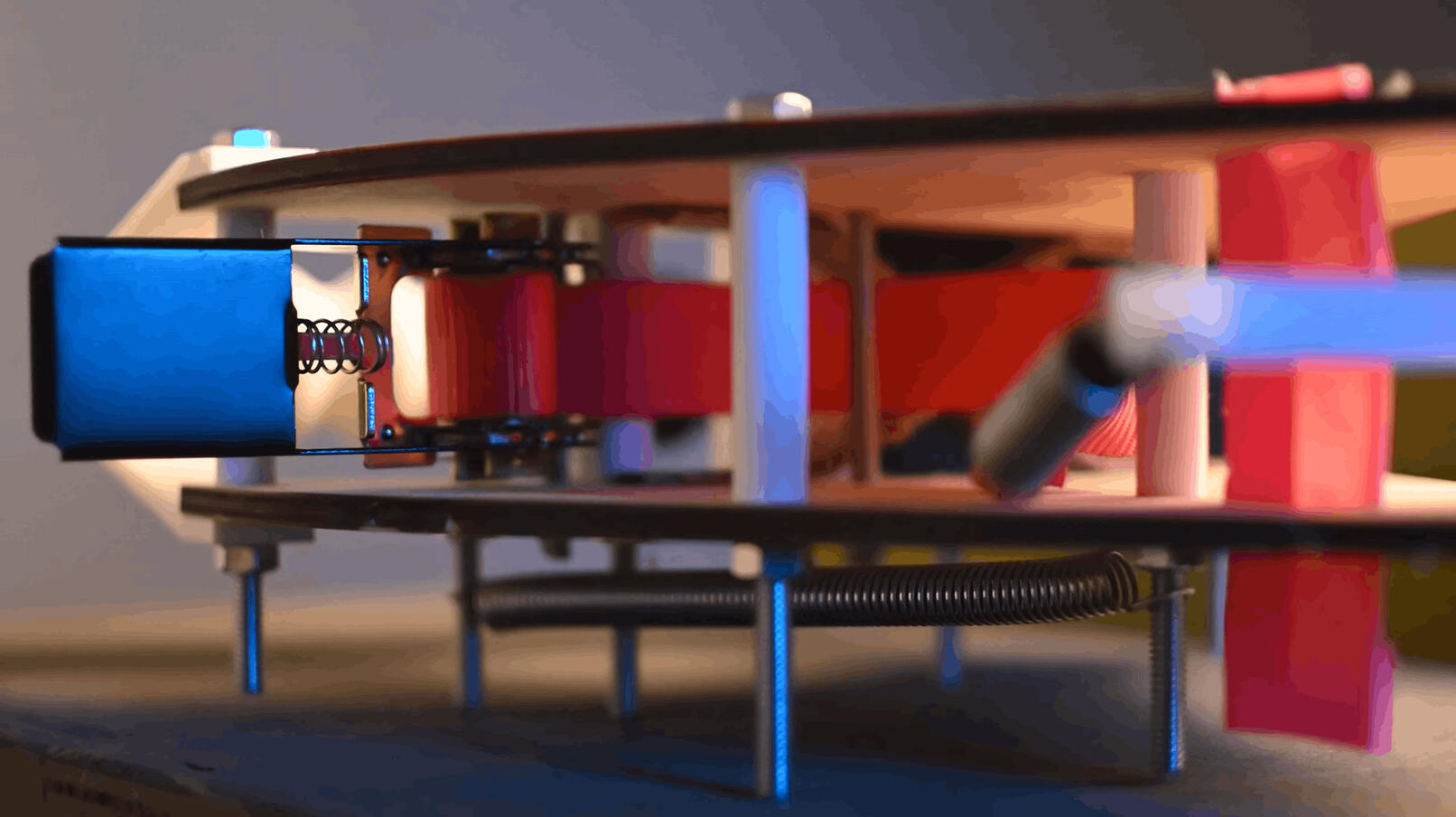

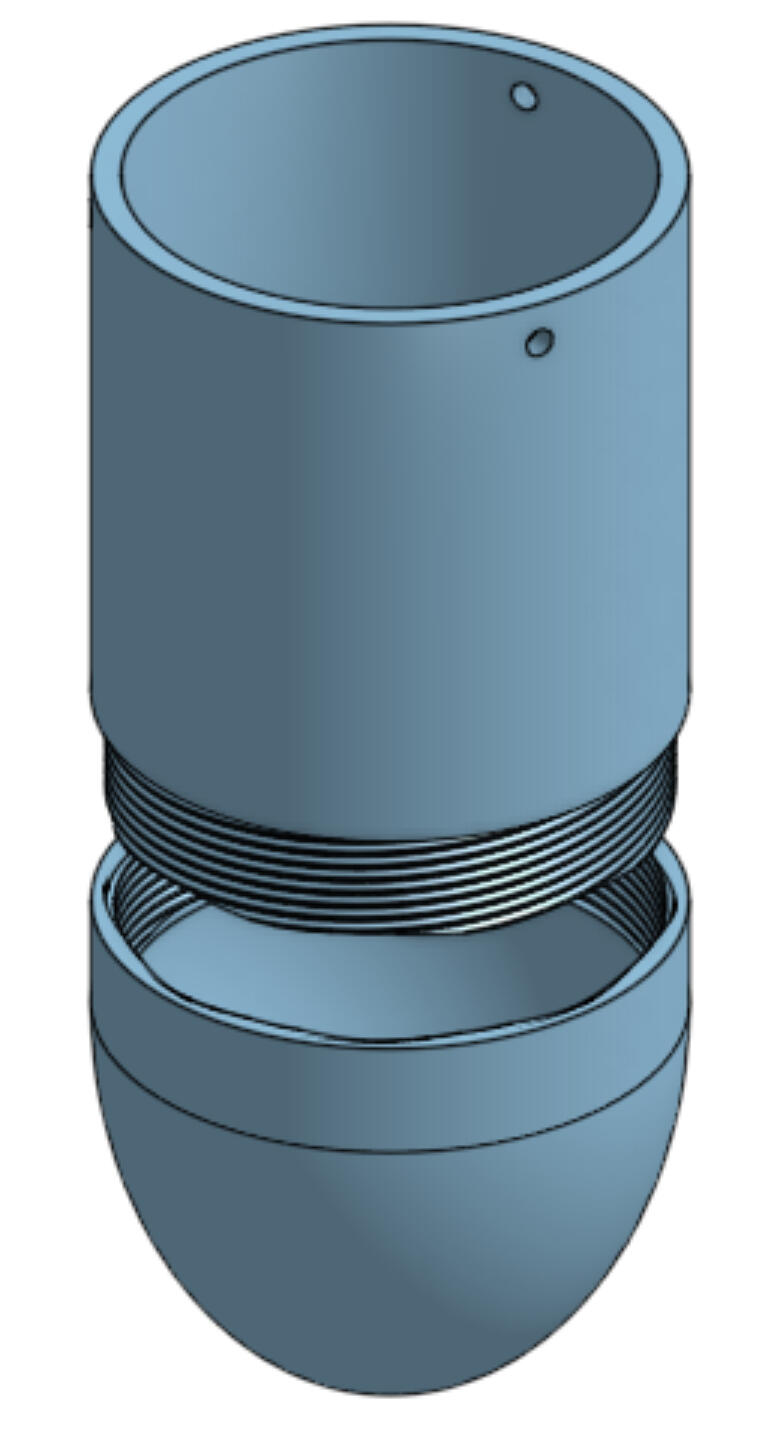

How it Works

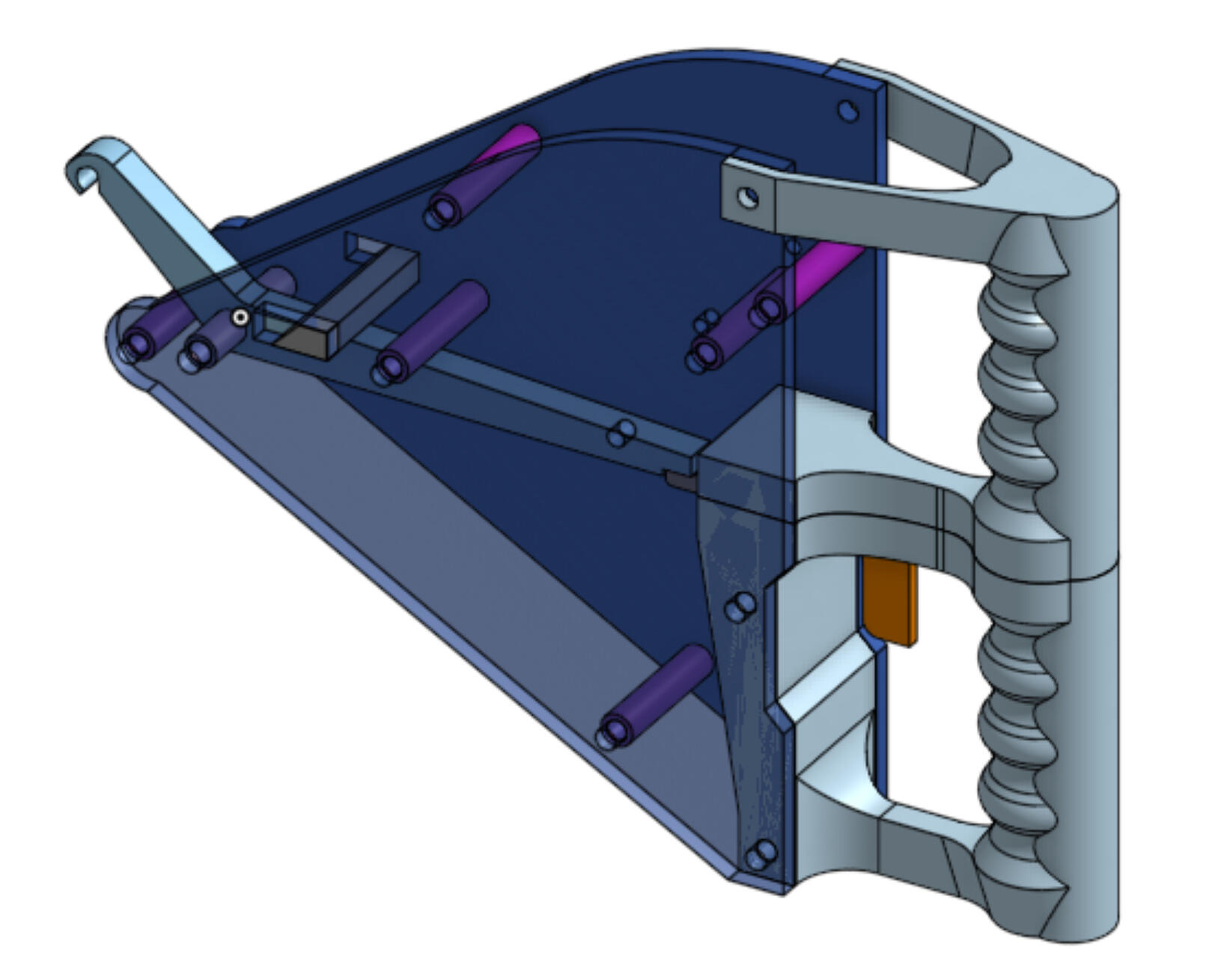

By cranking the ratchet, the strap wrapped around the ratchet is attached to a spring, which thus puts tension on the spring, priming the mechanism. The spring is attached to the upper end of the arm, while the lower end of the arm presses up against the trigger. Thus, as soon as the trigger is pulled, the mechanism will actuate, with the spring recompressing and the arm swinging forward.

Our Process

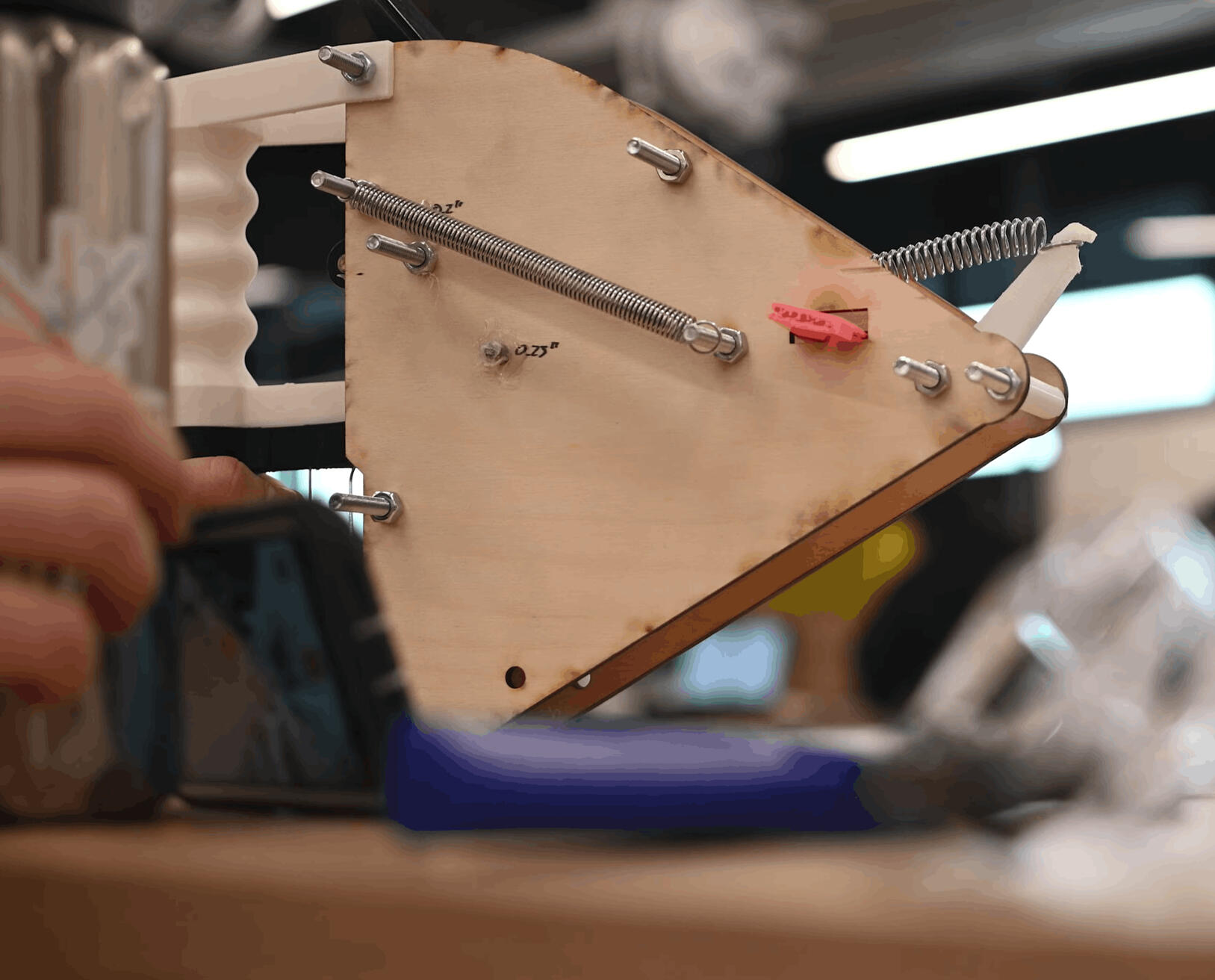

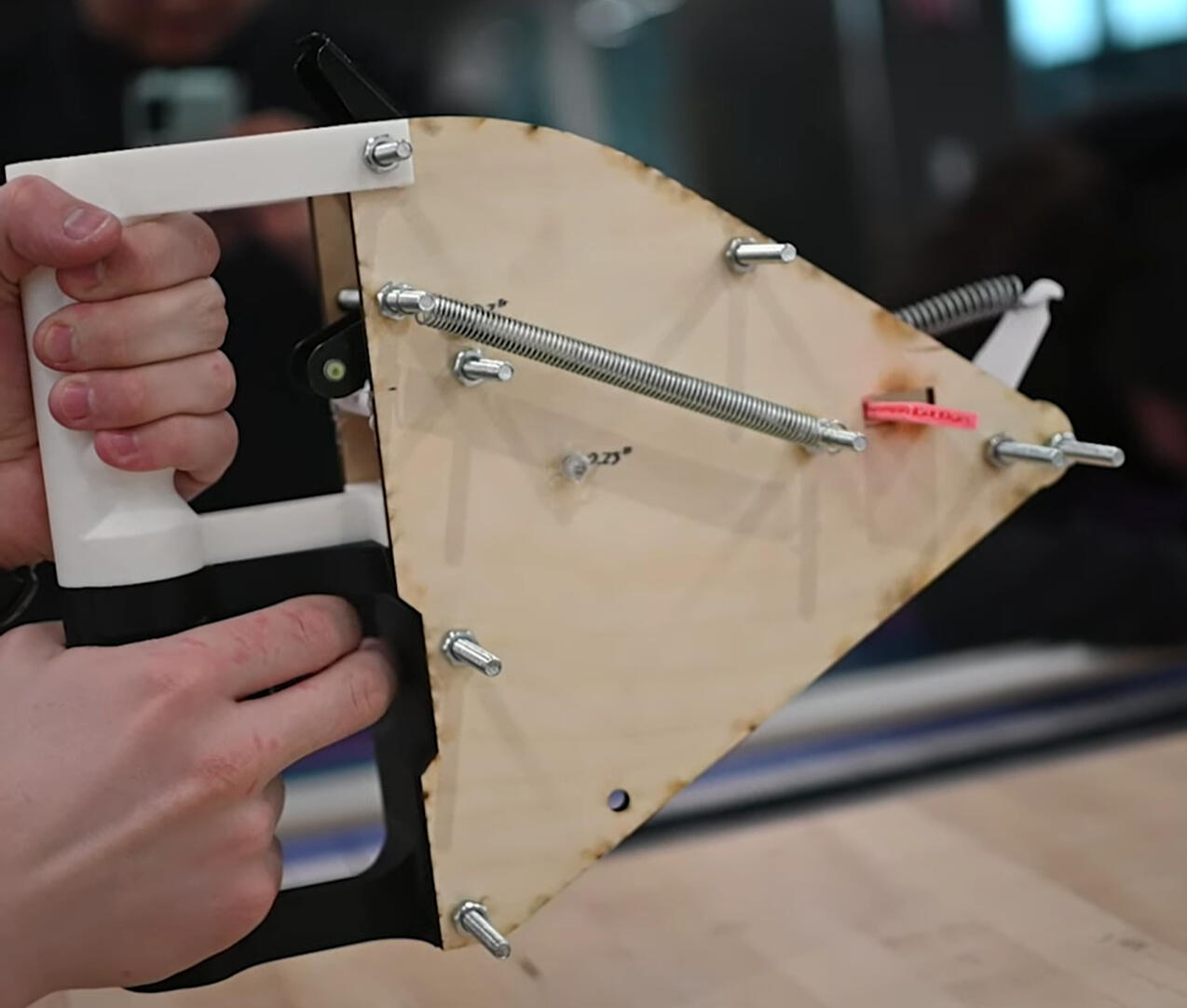

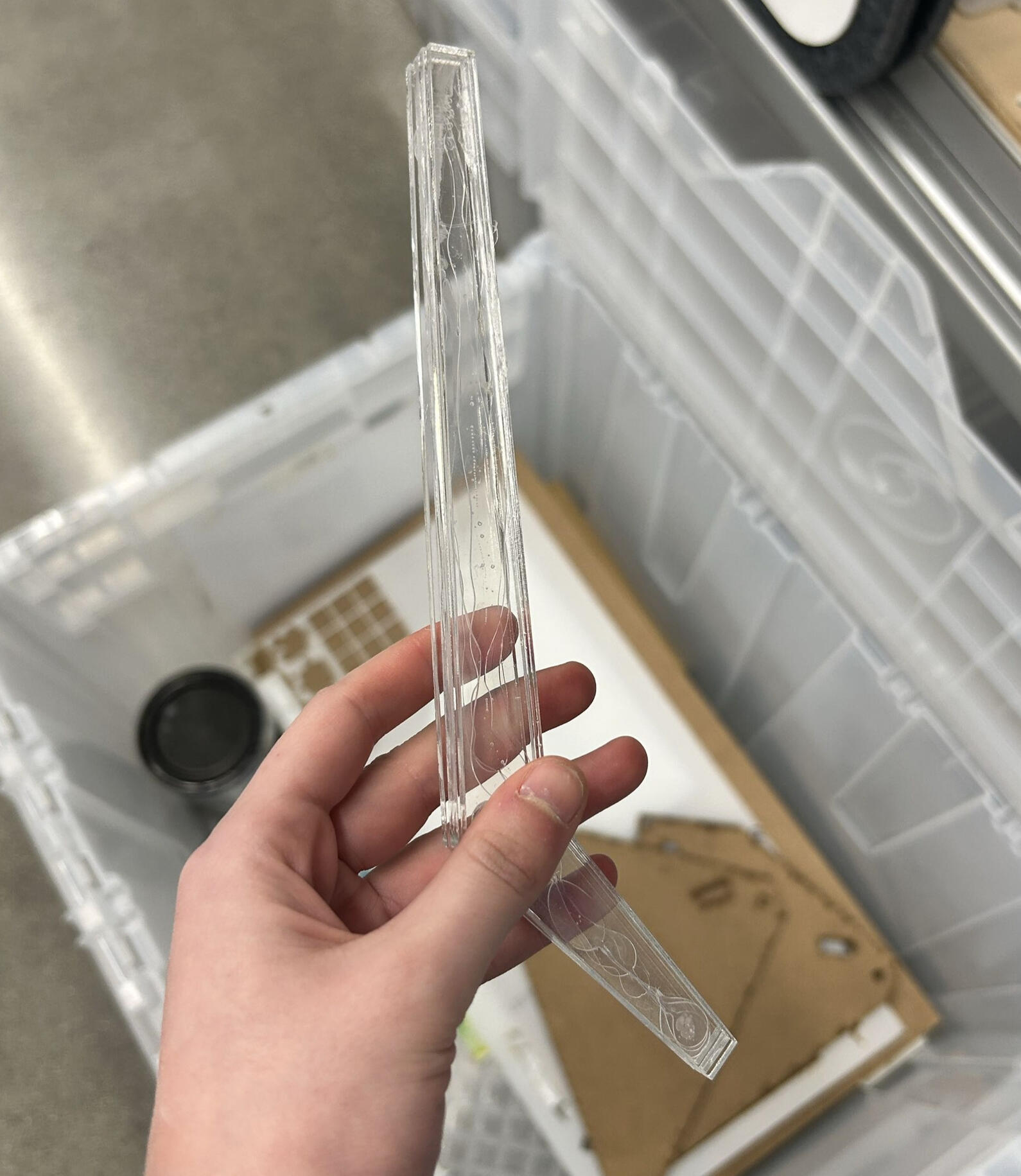

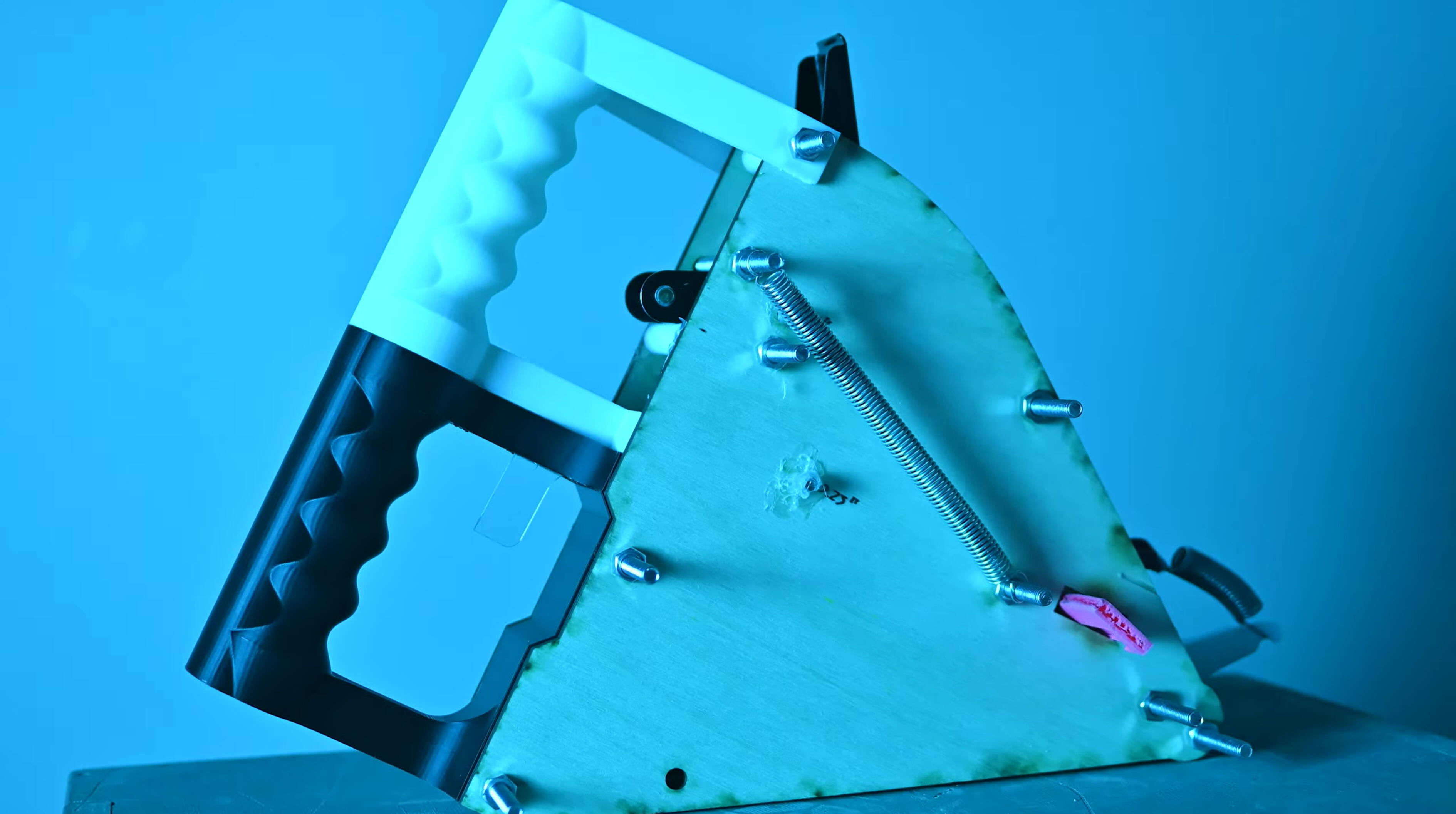

Unfortunately, after our initial test, the acrylic arm snapped, likely due to its poor impact strength at our speed. Additionally, the triangular models were quite bulky, thus we refined it into a much more rounded and ergonomic shape, while remaking the trigger out of a polyeurathane cutting board. The handles were also reprinted to fit the new side panels, and this time featured grips. We planned out how all the components would fit together, as well as the designs of the handles, arm, trigger, and side panels in Onshape. This allowed for easy collaboration and sharing of ideas and files.

To solve the problem of the broken arm, we researched what materials could withstand high impact stress, and came up with a few options: aluminum, and polyeurathane. While aluminum would be preferred for a realistic scenario, it was not within our budget to have a custom cut piece of aluminum in our build. Thus, we sourced a cutting board from our local hardware store made of polyeurathane, and using a combination of a band saw, drill press, and printed/cut solidworks drawing, we produced a new arm.

Our proto-prototype was made of cardboard, and relatively weapon shaped, which we decided to change upon feedback from our class and professor. Our second prototype was much more triangular, with an aim to have handles above and below the mechanism. It was modeled in Onshape before being laser-cut. The trigger and arm were laser-cut acrylic, while the side panels were cut out of MDF.

Our assignment required that we exhibit an exploded view created using SolidWorks in our final video, so we ported the files from Onshape into SolidWorks by saving each part as a SolidWorks part file, then assembled them in an assembly file, adding bolts and nuts using the SolidWorks toolbox. After finalizing our design (showcased above), we laser cut the final side panels out of MDF because that had worked well for previous prototypes. We used the trigger from the second prototype which had been laser cut out of acrylic and glued together, because it worked perfectly and didn't need any updates. We 3D printed the handles on a Bambu Lab printer, which allowed for minimal imperfections.

Hanging Planters

The initial motivation behind this project was the rising costs of living, and my new apartment's kitchen. Having a kitchen meant buying groceries and cooking, but with the rising costs of living, I was debating going without seasonings on any of my food. That is when I stumbled across herb seed packets at my local hardware store, and decided to just grow my own.In a small apartment, space is a challenge. With no lack of window space, but a complete lack of windowsill space, hanging planters were sounding like the best choice, until I realized that most herbs need to be potted in a planter that can drain. Nearly all planters on todays market don't have any way to drain water out of them without the water just ending up on the floor. Hence I designed my own.

Process

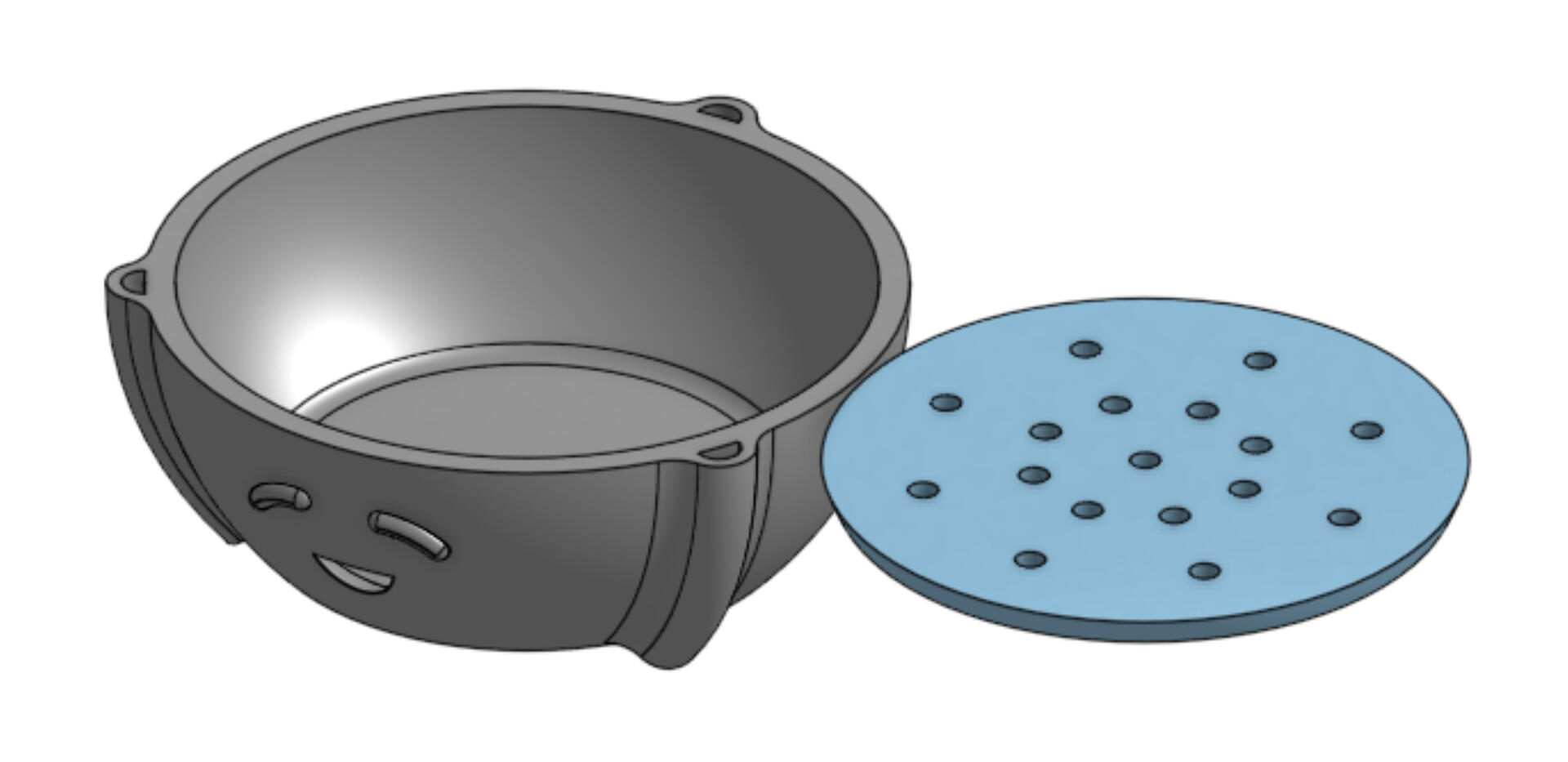

There are various ways to get water to drain out of a planter, but it is important that the rope which the planter hangs from doesn't block the access to the water. My initial idea was to utilize a mouth-like hole underneath a grate near the bottom of the planter, so the planter could be split into two sections: one for the plant and dirt, and the other for the water drainage. The water could pass through the grate, but the large pieces of gravel at the bottom of the dirt couldn't, and the gravel would hold the dirt above it and prevent it from washing through the grate.

I am currently working on further designs of hanging planters for my other herbs: chives, oregano, and rosemary. I will likely continue to use some form of grate to seperate the water from the soil, however where the water goes next will vary by design. I am hoping to create a water collection that hanges on a hinge, which can thus allow the basin to tip and pour out water while not tipping the section of the planter where the plant is located.

While this system worked well, it didn't work for the herbs. Herbs need deeper soil, and that design didn't allow for that. Thus, I created another version, this one with a screw on water catch, so that in case it overflowed, it would just bottom water the plant instead of getting all over the ground (which was another issue the previous design had).I also ended up repurposing the previous planter design for a string of pearls plant, which doesn't require very deep soil. However, this later proved to be too shallow a pot for even the string of pearls plant, so I ended up redesigning it to be a bit deeper, resulting in a more rounded shape of the pot.

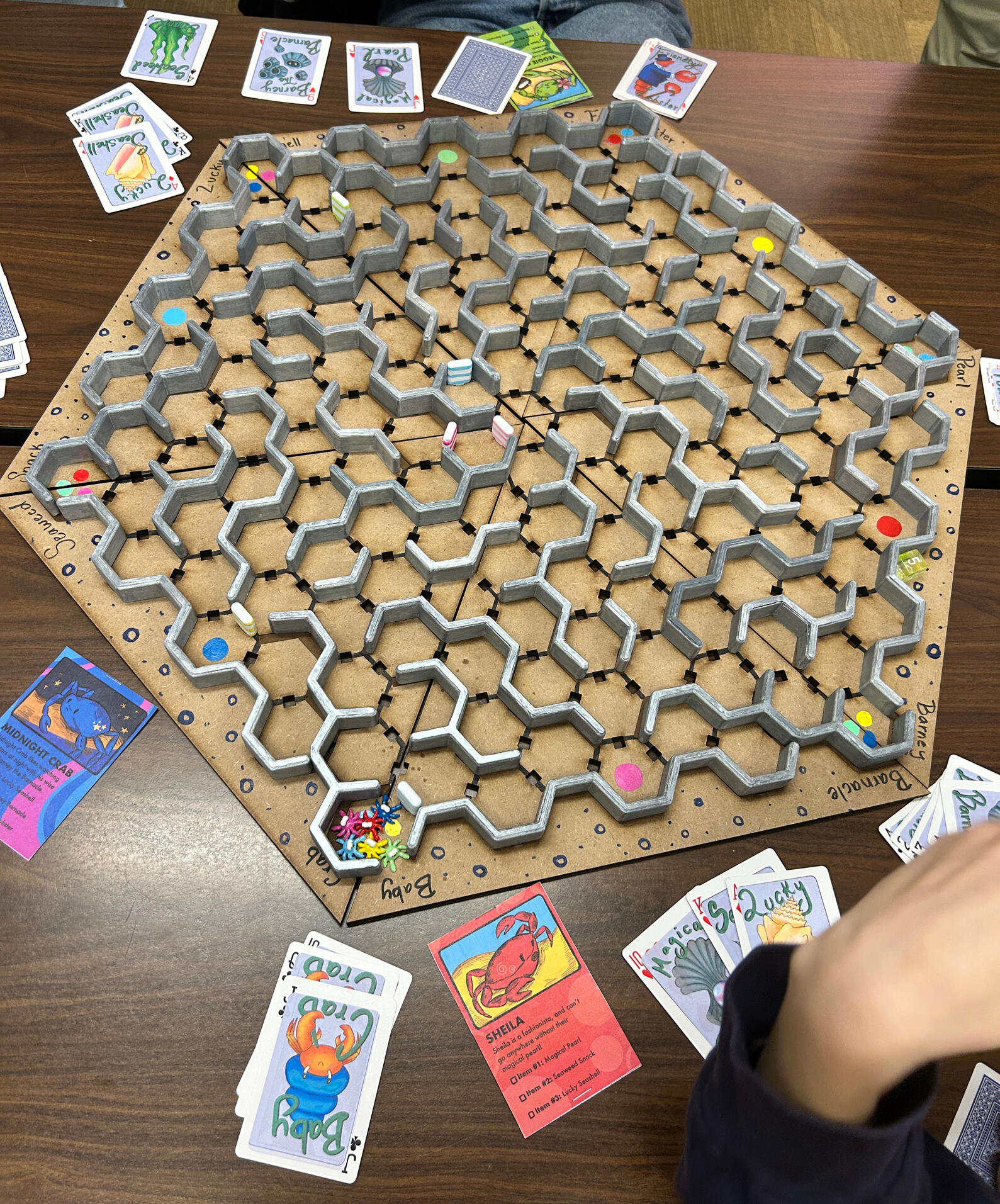

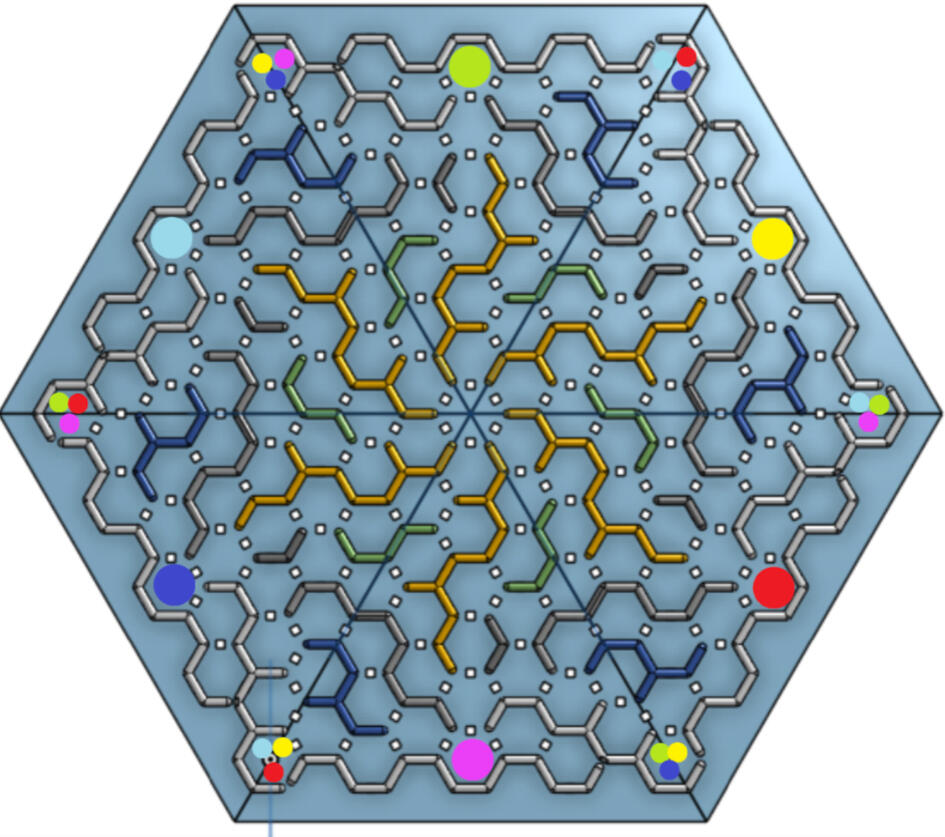

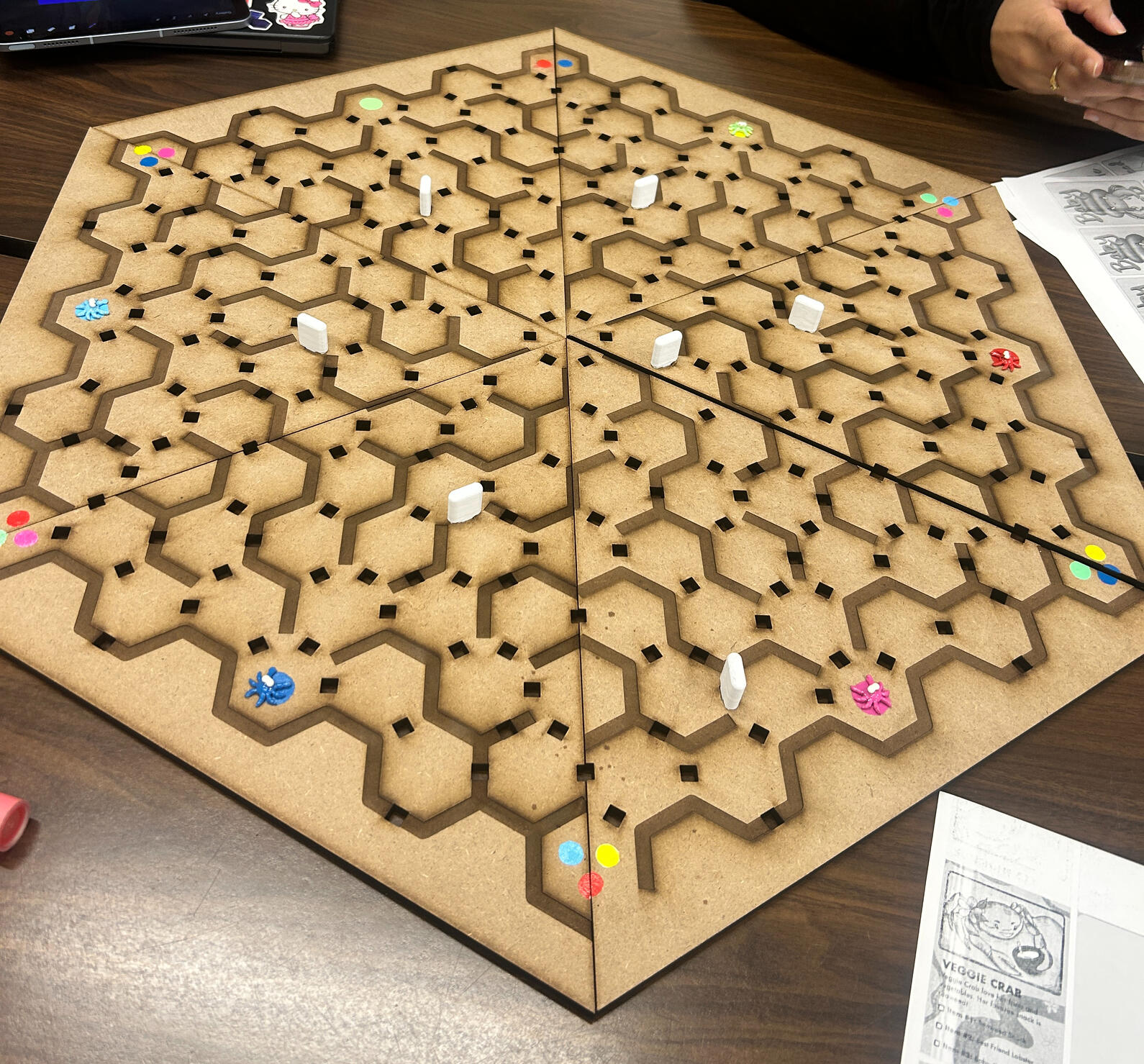

Crabs in a Bucket

This board game was created for a class I took: Design Perspectives Seminar. The assignment was simply to create a game, whether it be a board game, card game, or a game utilizing completely new tools was up to us. My group of five decided to make a labyrinth-based board game which we eventually dubbed "Crabs in a Bucket", due to how the gameplay reminded us of crabs scurrying around the inside of a child's bucket after being caught. It is a strategy game at heart, with quite a bit of randomness thrown in to spice it up and make each game a bit different.

My Process

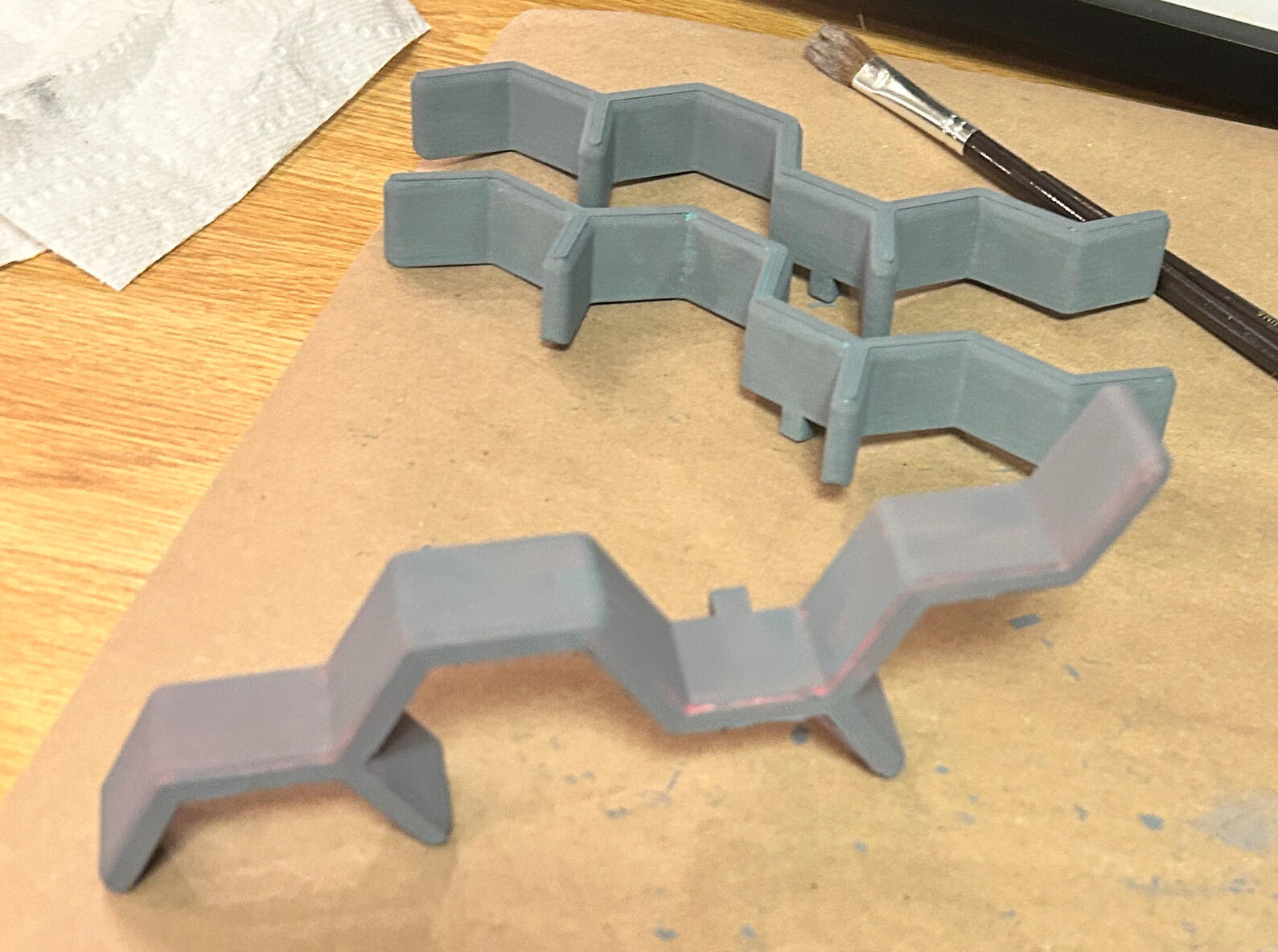

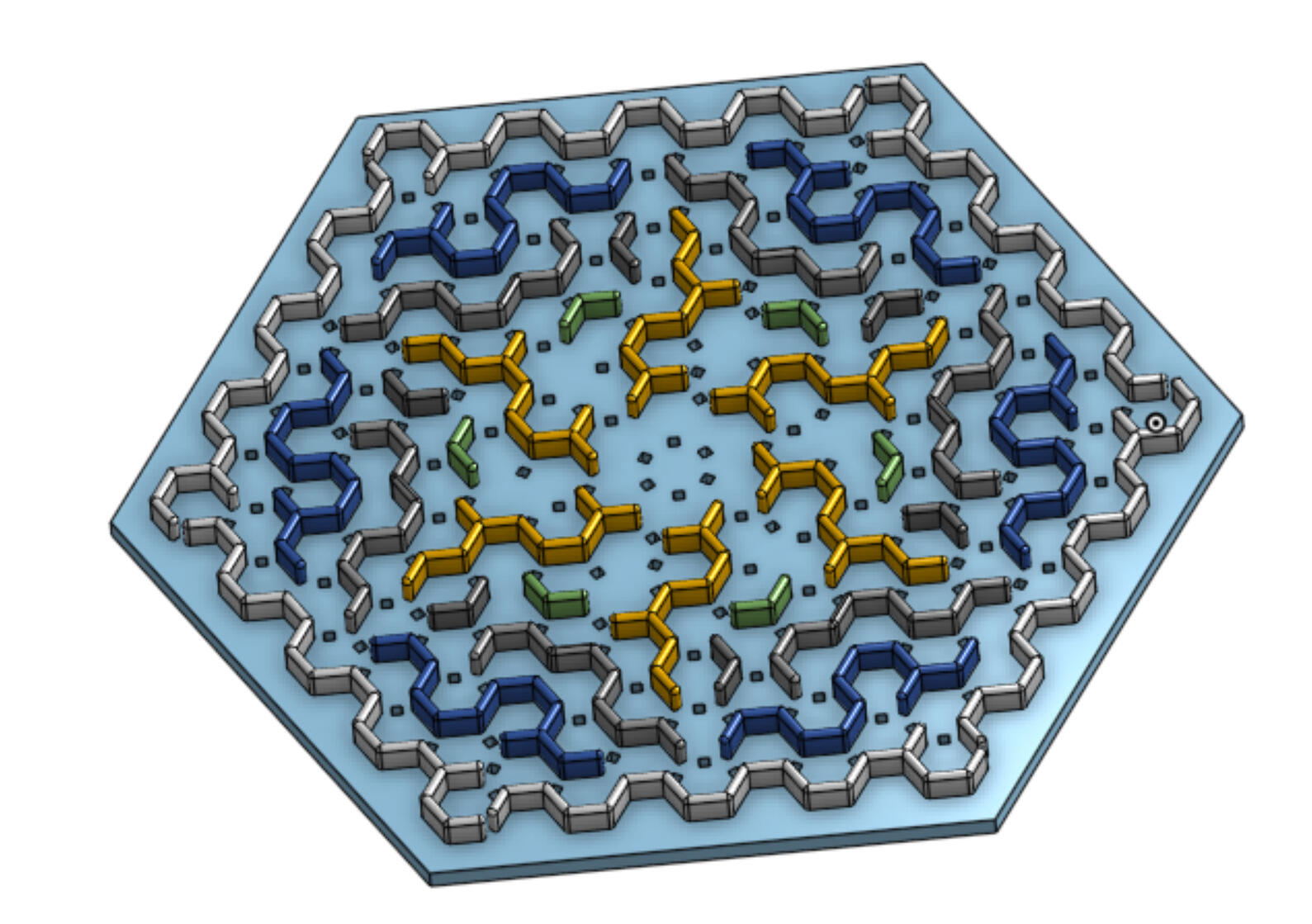

My role within this project was to build the board and the walls. This required me to consider tolerances between the walls and the board itself, as well as manufacture each piece, and design the layout of the labyrinth.I began by researching labyrinths, and decided upon making a hexagonal tileable design, so that each tile was triangular. Then, after designing the labyrinth in Onshape, I planned out each item's location, and each crab's starting position, to make sure that each crab would travel the same distance to each item. Because of the tileable nature of the design, this was pretty simple, because it meant the distance between each corner or center of each tile was the same between tiles.

Then, I laser cut the board out of MDF, and slowly watched the project come together. While there were a couple errors in the design (a missed hole and a missed engraving to mark where part of a wall would go), those errors didn't impact the performance of the project.Another part I was responsible for was the resin printing of the crab pieces. This part consisted primarily of sourcing the file, confirming its approval with my groupmates, and then getting it printed in the Northeastern CAMD Ryder makerspace.

Once the design was finalized, I had to make sure that the pegs for each wall fit the holes in the board. I did some research for tolerances in 3D printing and compared them to the tolerances used in laser cutting, and discovered that roughly a 0.02 in tolerance should work for our purposes.I 3D-printed the walls, sanding and painting them as I went, first with two layers of grey and then with two layers of silver.

The removing of the supports from the finished print was easily one of the most physically difficult parts of this project. The supports for the prints were about the same diameter as the legs of the crabs, so it was extremely difficult to not accidentally snap the legs or arms of the crabs as the supports were being removed.While several crabs were lost in the process, we did eventually get the full six crabs finished and ready for painting. The painting was done with acrylic, and then finished with clear nail polish to prevent scratching.

How it Works

These items are placed around the board in such a way so that no crab has to travel any farther than another, and are indicated by colored dots matching the assigned crabs' colors, as well as writing of the item's name behind the space. There are also cards of each item, which players collect as their items, and discard an Action card as they do so.Each player starts with 3 Action cards, which allow them to build walls, remove walls, move walls, move other players, and other fun actions. At the start of their turn, they can chose between playing a card or rolling a die to move their crab.The game ends when a player collects all their items and goes to the center of the board. When in the center space, with all their items, they win.

Players begin by chosing their crab, each of which has a Character Card and a game piece that matches the Character Card. No crab has an advantage over one another: the only differences are how we describe each crab, and their color. On their character card, a list of 3 items is given which the player must collect before they can "escape" the "bucket".

Video Game Curriculum

Video games have been a big part of my life for as long as I can remember. When I was making my own for a personal project my senior year of high school, I noticed that a lot of students took interest in my work and wanted to learn how to do what I was teaching myself: making video games. Thus, I took it upon myself to write a curriculum on how to do so as my Senior Choice Of Related Experience project (SCORE).I have written curriculums in the past for sailing classes, but teaching in a pure classroom setting was something that was relatively new to me. Additionally, the curriculums I had focused on as a sailing instructor were for students ages 6-12, not 16-18. Regardless, I knew the same principles of balancing kinesthetic, visual, auditory, and written/reading are required in order for anyone to be able to obtain any skill.Because I believe that everyone should have a right to education, I have made this curriculum free to download. It is designed to guide a high-school class, and can either be handed out to students to follow individually, or be followed and/or modified by a course instructor. It can also be followed independently by anyone who is interested in learning how to make video games using Unity. It is important to note, however, that this curriculum was written in 2024 and therefore utilizes the 2024 version of Unity.